PROLASER CLEAN

DXB

Revolutionizing Surface Cleaning with Laser Technology

Introduction to Laser Cleaning

Laser cleaning is an advanced, non-contact surface treatment technology that uses focused laser beams to remove unwanted layers such as rust, paint, oil, oxides, or other contaminants. Unlike traditional cleaning methods - such as sandblasting, chemical stripping, or abrasive brushing - laser cleaning is highly selective, allowing contaminants to be removed without damaging the underlying material.

This precision makes it particularly valuable for delicate surfaces, high-value components, and applications where preservation of the base material is critical.

How It Works

Laser cleaning relies on the interaction between high-powered laser light and the surface material. A laser beam is directed onto the surface to be cleaned, and the energy from the laser causes the contaminants on the surface (such as rust, dirt, oil, paint or other unwanted layers) to be vaporized or ejected without damaging the base material.

Laser Emission

A laser source generates high-energy light, typically in the form of short pulses or continuous beams.

Surface Interaction

The laser light is directed at the surface where contaminants are present. The laser's energy is absorbed by the material on the surface, creating a high temperature that causes the contaminants to either vaporize or be physically removed.

Key Benefits of Laser Cleaning

Eco-Friendly & Sustainable

- •No chemicals or solvents

- •No secondary waste disposal required

- •Reduces environmental impact

- •No exposure to toxic chemicals

Non-Abrasive & Safe for Surfaces

- •Protects delicate materials (e.g. historical artifacts, aerospace components)

- •No damage to base material compared to sanding or grinding

Cost-Effective & Low Maintenance

- •Reduces long-term maintenance costs

- •No need for consumables (sand, chemicals, water)

- •Longer lifespan of cleaned surfaces

High Precision & Automation Compatibility

- •Selectively removes contaminants, ideal for delicate or intricate surfaces

- •Can be automated for industrial applications

Comparison to Traditional Methods

Sandblasting

Involves blasting sand particles at high velocity, which can be abrasive and may cause damage to delicate or softer surfaces. Generates significant dust and particulate matter, posing serious respiratory hazards.

Chemical Cleaning

Many chemicals used for cleaning can be toxic and pose serious health risks if inhaled, ingested, or absorbed through the skin, resulting in potential environmental harm.

Pressure Washing

Water can infiltrate cracks, causing hidden damage or mold growth. Potential damage to delicate surfaces and uses large amounts of water with chemical runoff that can pollute the environment.

Industries We Serve

Laser cleaning is a versatile and advanced technology that is being adopted across a wide range of industries due to its precision, efficiency, and environmental benefits.

Manufacturing Industry

Surface preparation, tool and mold cleaning, precision cleaning for components requiring careful handling.

Aerospace & Automotive

High-performance component cleaning, coating removal, rust and corrosion treatment.

HoReCa Industry

Commercial kitchen equipment, ventilation systems, and food processing area maintenance.

Residential

Home maintenance, restoration, and cleaning services for various household surfaces.

Case Studies & Success Stories

See the remarkable transformation results achieved with our laser cleaning technology across different applications.

Example 1: Automotive Parts Maintenance

Challenge:

Rust and oil removal on car parts before repainting.

Solution:

Laser cleaning provided a fast, uniform cleaning process.

Result:

Removed rust, oil and dirt and reduced material waste.

Example 2: Residential/Commercial - Travertine and Marble

Challenge:

Dirt and grime removal on travertine and marble used for outdoor areas.

Solution:

Laser cleaning provided a fast, uniform cleaning process.

Result:

Travertine, in particular, has a porous and textured surface, but laser cleaning accessed these hard-to-reach areas, ensuring a thorough clean.

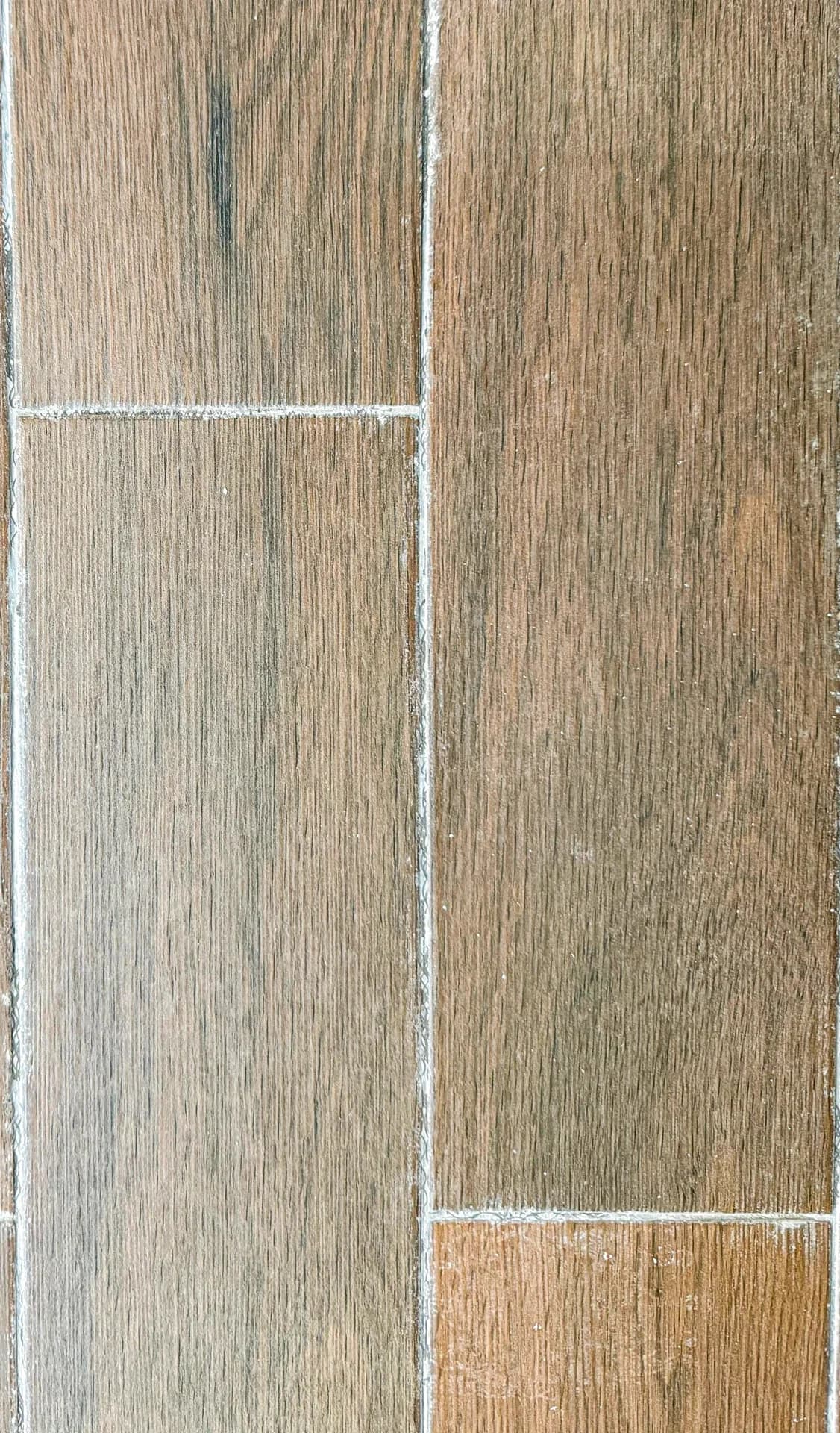

Example 3: Residential Laser Cleaning - Floor Tiles

Challenge:

Removing hard residue from floor tiles after renovation. The client tried for more than 8 years to find an effective cleaning solution for the tiles.

Solution:

Laser cleaning allows for spot cleaning of hard residue on the tiles.

Result:

The laser removes residue without abrasive tools, protecting the surface of the tiles from scratches or wear.

Example 4: Limestone (building facades, monuments, floors)

Challenge:

Limestone is soft and porous, easily damaged by abrasive cleaning or chemicals. Needs careful soot, pollution, and biological growth removal without eroding details.

Solution:

Applied controlled laser parameters with gradual passes to lift surface contaminants while protecting the substrate.

Result:

Surface soils and soot removed while preserving stone color, carvings, and tool marks. No chemical residues, minimal dust, and improved longevity of the stone surface.

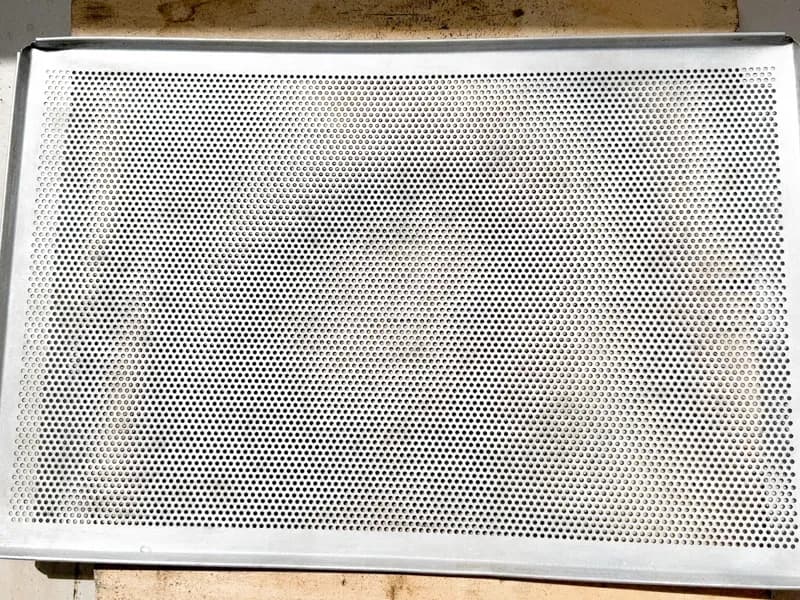

Example 5: Bakery Tray (metal baking trays with carbonized residues/oils)

Challenge:

Carbonized dough, grease, and burnt-on food residues stick firmly to trays. Abrasives can thin the tray, chemicals risk contamination.

Solution:

Used laser cleaning to break down and remove surface build-up without abrasive media or chemicals.

Result:

Trays are restored to clean metal, free of residues, without wear or deformation. Hygiene improves, trays last longer, and cleaning downtime is reduced compared to caustic soaking.

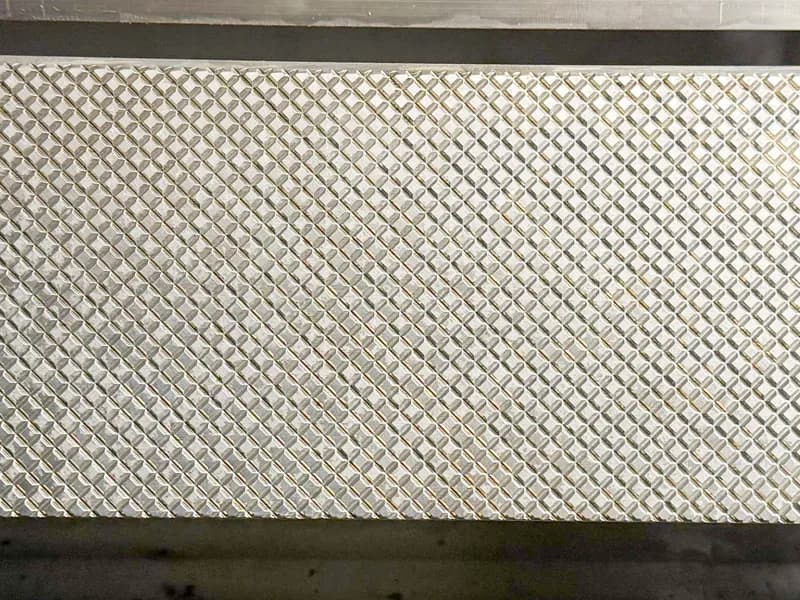

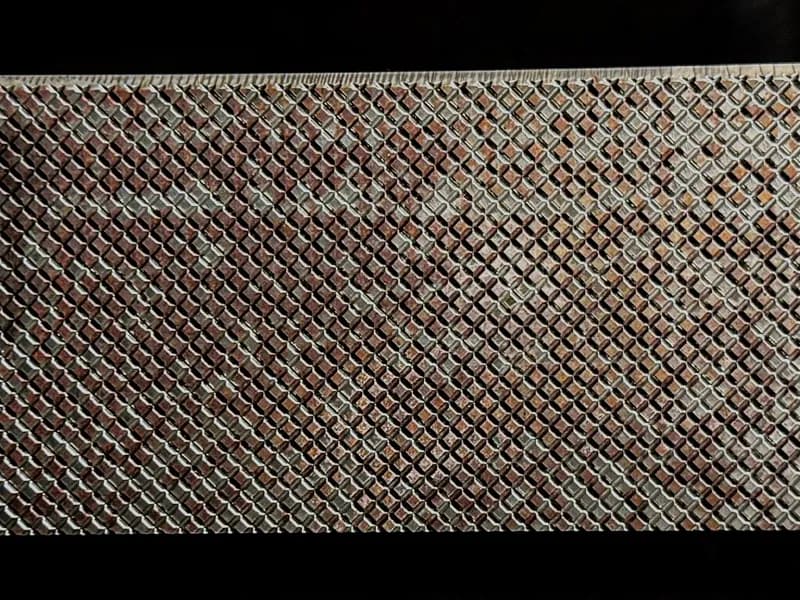

Example 6: Bakery Production Line (conveyors, stainless steel, machinery parts)

Challenge:

Oils, flour dust, and baked residues accumulate on belts, rollers, and stainless-steel surfaces. Traditional cleaning (water, chemicals) risks contamination and requires downtime.

Solution:

Deployed non-contact laser cleaning to safely remove contaminants in sensitive food production environments.

Result:

Equipment surfaces are sanitized and residue-free without chemicals. Reduced downtime, improved food safety compliance, and longer equipment life. Production can restart quickly after cleaning.

Example 7: Travertine with Epoxy Coat (epoxy removal)

Challenge:

Epoxy coatings penetrate the porous structure of travertine. Mechanical removal risks gouging the soft stone, and chemical strippers can stain or weaken it. The goal is to strip epoxy without harming the stone surface.

Solution:

Used laser cleaning to selectively ablate the epoxy layer while minimizing impact on the natural stone.

Result:

Epoxy layer removed cleanly, travertine pores reopened, and the natural texture preserved. No chemical residues left behind, and the stone remains ready for restoration or re-coating.

Example 8: Metal Car Parts (engine, chassis, body components)

Challenge:

Rust, grease, paint, and oxide layers reduce part performance and complicate repairs or recoating.

Solution:

Applied laser cleaning to precisely remove unwanted layers without damaging the base metal or altering dimensions.

Result:

Clean, rust-free surfaces that are ready for welding, coating, or assembly; improved durability and reliability of parts.

Contact Us

At PROLASER CLEAN DXB we specialize in providing cutting-edge laser cleaning technology to meet all your cleaning needs with precision, efficiency, and sustainability.

Why Choose Us?

Advanced Technology

We use the latest laser cleaning equipment for precise, efficient removal of stubborn residues without damaging surfaces.

Eco-Friendly

Our process is chemical-free and generates no waste, making it safe for the environment and your property.

Fast & Efficient

We deliver quick, effective results, reducing downtime and lowering costs compared to traditional methods.

Experienced Team

Our skilled team is expert in laser cleaning, ensuring high-quality service.

Custom Solutions

We provide tailored cleaning for various surfaces and industries, offering the best solution for your project.

Choose us for a cleaner, safer, and more sustainable approach to cleaning - contact us today to learn how we can help!

Get In Touch

Phone Numbers

Website

Location

Get Your Free Quote

Tell us about your project and we'll provide a customized solution for your cleaning needs.